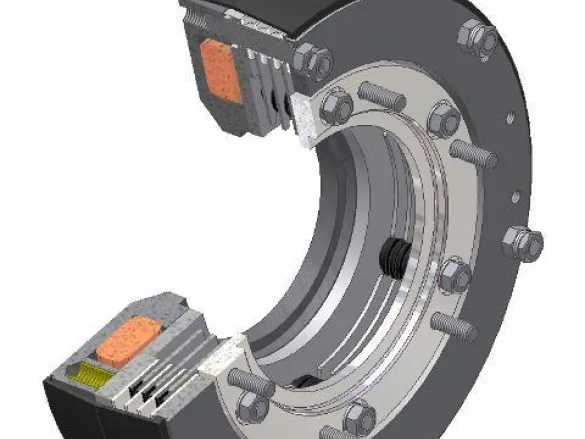

OMB/OLB, OLK/OLG Especially for mechanical and apparatus engineering

Protection class

The PRECIMA electromagnetic clutches and electromagnetic brakes have been specially developed for the requirements of modern mechanical and apparatus engineering.

Due to their interesting price/performance ratio, work-current-actuated clutches and brakes are the optimal solution for starting, braking, positioning, and securely holding masses for shaft and flange-mounted installation in plant and mechanical engineering.

These clutches and brakes use the power flow of an electromagnet concentrated on pole faces for a non-positive connection of shafts and hubs in the torque range from 7.5 to 120 Nm.

This product maturity is particularly evident in extreme applications, where short switching cycles are required with maximum of safety standards.

Due to the high-quality standards in development, material selection and production, they meet all the demands of today's drive technology.

| Size | Braking torque [NM] | Outer diameter [mm] | Height /armature F2 [mm] | Height /armatureF1 [mm] | Height /armature 0 [mm] |

|---|---|---|---|---|---|

| 65 | 7,5 | 80 | 31,7 | 43 | 28 |

| 80 | 15 | 100 | 35 | 51 | 31 |

| 100 | 30 | 125 | 40,7 | 61 | 36 |

| 125 | 60 | 150 | 46,3 | 70,5 | 40,5 |

| 160 | 120 | 190 | 54 | 85 | 47 |

Dimensions in the table [mm]

* Tolerances of the braking torques, see operating and assembly instructions

** Keyway according to DIN 6885, sheet 1

Holding brakes = standard braking torque Mb * 1.5

Installation position of the hub according to the operating and assembly instructions

| Size | Braking torque [NM] | Outer diameter [mm] | Height /armature F2 [mm] | Height /armature F1 [mm] | Height /armature 0 [mm] |

|---|---|---|---|---|---|

| 65 | 7,5 | 68 | 67,7 | 59 | 44 |

| 80 | 15 | 87 | 73,7 | 68,5 | 48,5 |

| 100 | 30 | 108 | 84,7 | 80 | 55 |

| 125 | 60 | 135 | 96,8 | 92 | 62 |

| 160 | 120 | 170 | - | 111 | 73 |

Dimensions in the table [mm]

* Tolerances of the braking torques, see operating and assembly instructions

** Keyway according to DIN 6885, sheet 1

Holding brakes = standard braking torque Mb * 1.5

Installation position of the hub according to the operating and assembly instructions

| Size | Braking torque [NM] | Outer diameter [mm] | Height /armature F2 [mm] | Height /armature F1 [mm] | Height /armature 0 [mm] |

|---|---|---|---|---|---|

| 65 | 7,5 | 80 | 51,7 | 43 | 28 |

| 80 | 15 | 100 | 56,2 | 51 | 31 |

| 100 | 30 | 125 | 65,7 | 61 | 36 |

| 125 | 60 | 150 | 75,3 | 70,5 | 40,5 |

| 160 | 120 | 190 | - | 85 | 47 |

Dimensions in the table [mm]

* Tolerances of the braking torques, see operating and assembly instructions

** Keyway according to DIN 6885, sheet 1

Holding brakes = standard braking torque Mb * 1.5

Installation position of the hub according to the operating and assembly instructions

| Size | Braking torque [NM] | Outer diameter [mm] | Height /armature F2 [mm] | Height /armature F1 [mm] | Height /armature 0 [mm] |

|---|---|---|---|---|---|

| 65 | 7,5 | 80 | 26,2 | 37,5 | 22,5 |

| 80 | 15 | 100 | 28,7 | 44,7 | 24,7 |

| 100 | 30 | 125 | 33,2 | 53,5 | 28,5 |

| 125 | 60 | 150 | 38 | 62,2 | 32,2 |

Dimensions in the table [mm]

* Tolerances of the braking torques, see operating and assembly instructions

** Keyway according to DIN 6885, sheet 1

Holding brakes = standard braking torque Mb * 1.5

Installation position of the hub according to the operating and assembly instructions

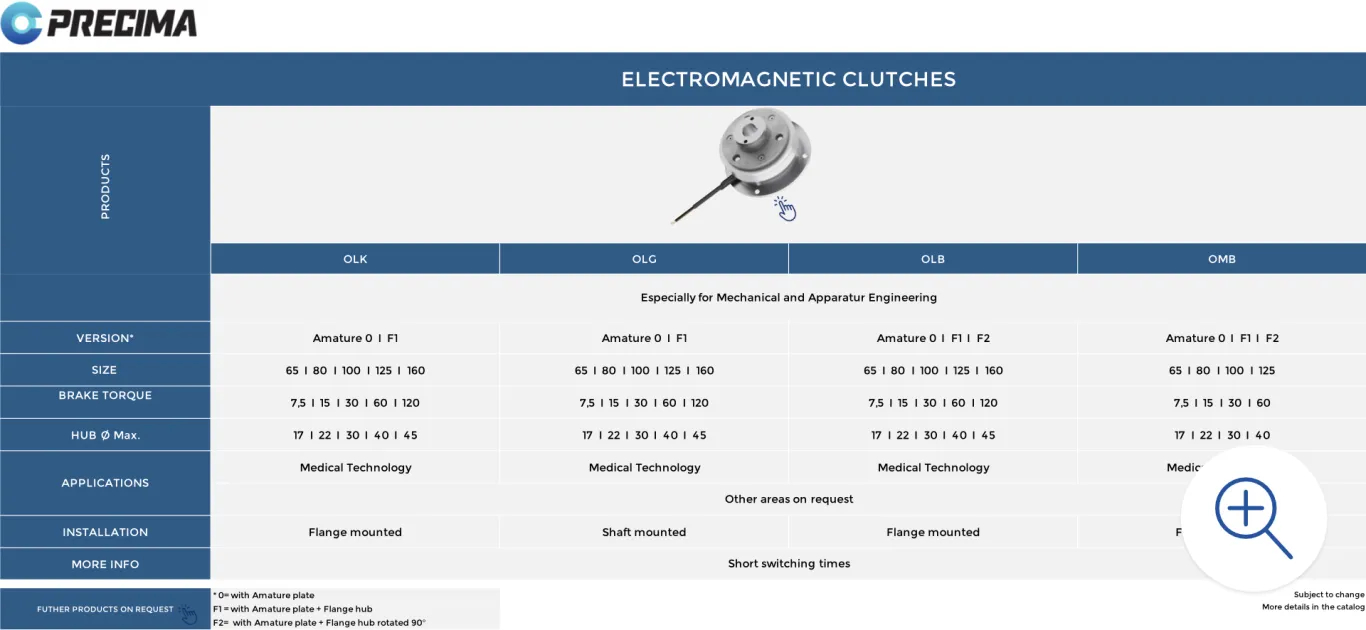

Product selection

Documentation & Downloads

Further Documents

You can access additional documents with a customer login for our service portal.