Spring-applied electromagnetic safety brakes

Electromagnetic spring-applied brakes / safety brakes / fail-safe brakes

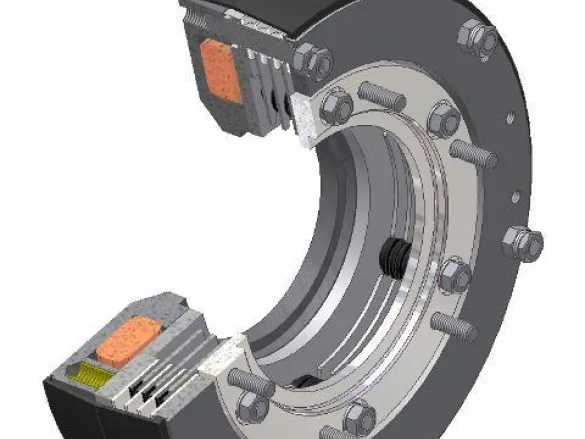

Spring-applied electromagnetic brakes manufactured by PRECIMA Magnettechnik are extremely reliable safety brakes that operate according to the fail-safe principle. As electromechanical brakes with two friction surfaces, they ensure secure holding and precise stopping even with high forces.

The electromechanical holding brakes and service brakes are active when de-energised and are released by an electromagnetic coil, which pulls the armature disc against the spring force when energised. This makes them particularly suitable for applications where safety must be guaranteed even in the event of a power failure. Electromagnetic spring-applied brakes thus enable safe and precise holding, stopping and positioning of moving masses.

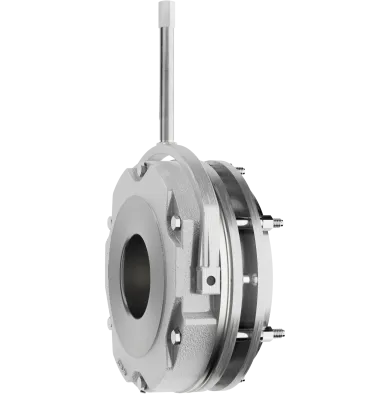

Depending on the area of application, our brakes are also known as spring-applied brakes, electric spring-applied brakes, power-off brakes, electromechanical safety brakes, electromagnetic holding brakes or electromagnetic service brakes. Thanks to their compact design, short switching times and very high reliability, PRECIMA spring-applied brakes are ideal for applications with high torques, under extreme environmental conditions or with increased safety requirements in various industries. Thanks to the flexible mounting options of our brakes, simple and reliable integration into almost any mounting environment is possible. We meet individual requirements through application-oriented development and application solutions for electromagnetic brakes that are precisely tailored to your challenges.

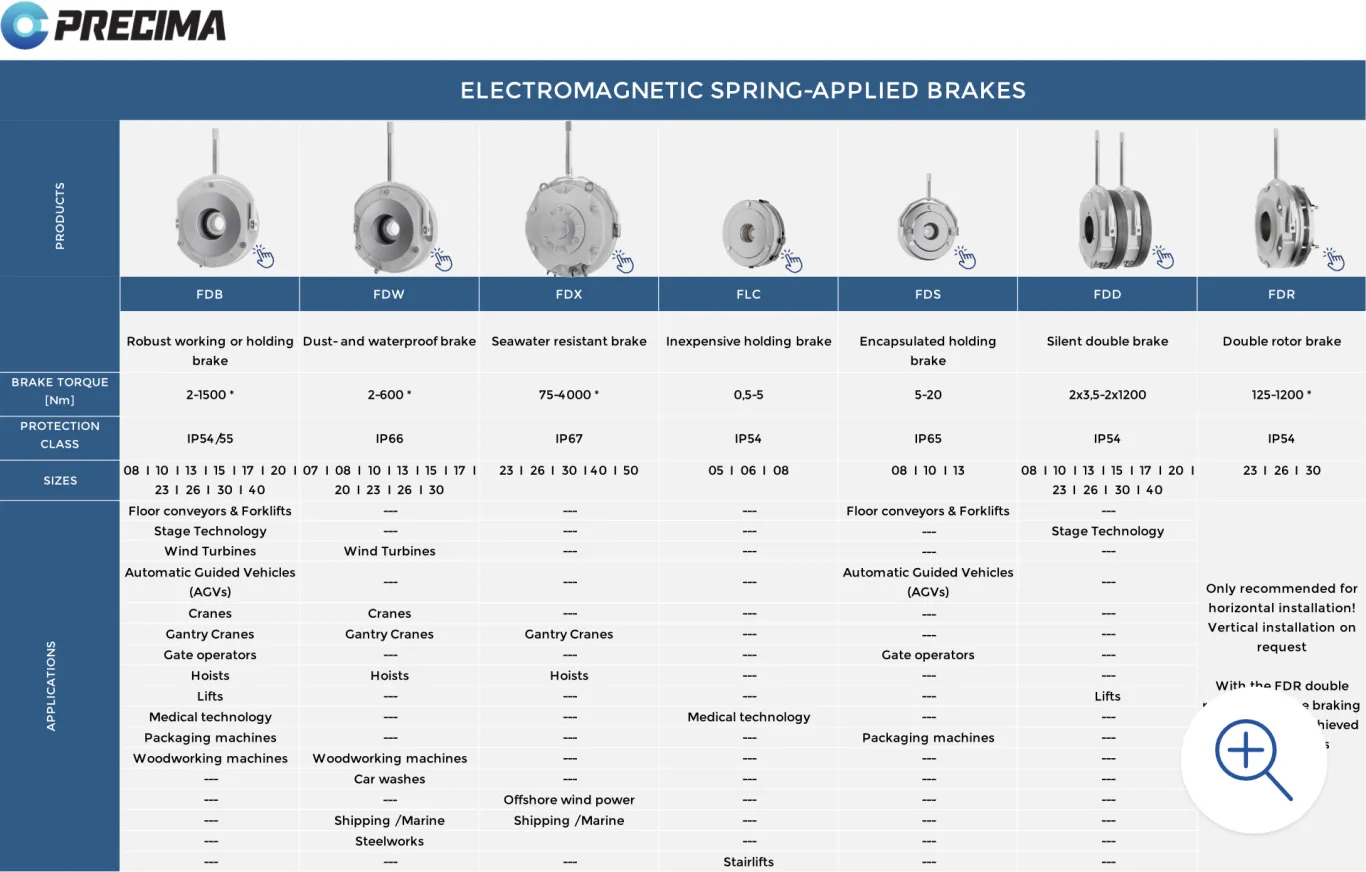

PRECIMA spring-applied brakes are known for their high quality and reliability, which is underlined by numerous international certifications for various series. Below you will find further information on our brake series, technical options, special suitability for specific areas of application and industries, as well as further details on our electromagnetic spring-applied brakes.